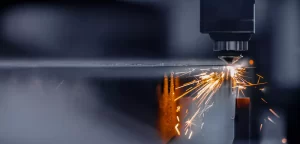

In the ever-evolving landscape of industrial manufacturing, freelance workers have emerged as key players in enhancing the operations of laser welding companies. The focus of this discussion is to uncover the secrets that can empower freelance workers to become invaluable assets in driving innovation and success within the laser welding industry.

By delving into the realm of industrial laser welding insights, we will explore how freelance workers can optimize welding parameters and leverage cutting-edge technology to elevate the craft of laser welding. Through a careful exploration of insider secrets and industry insights, we aim to shed light on the untapped potential of freelance workers in improving the performance of laser welding companies.

Let’s uncover the strategies that can make freelance workers instrumental in enhancing precision and efficiency in laser welding.

Key Takeaways

- Industrial laser welding offers precision, speed, clean welds, flexibility, and versatility, making it a desirable choice for various applications.

- Freelance workers in laser welding may face challenges such as limited access to equipment, lack of support and guidance, inconsistent work opportunities, technical expertise requirements, and the need for continuous professional development.

- To improve laser welding efficiency, optimizing welding parameters, leveraging automation and robotic systems, ensuring proper maintenance and calibration, using advanced monitoring and control systems, and utilizing simulation and modeling techniques are key insights.

- Technology can be leveraged to enhance laser welding performance through automation, real-time monitoring and control, simulation and modeling, cutting-edge tools and equipment, and continuous learning and staying updated.

Benefits of Industrial Laser Welding

The Benefits of Industrial Laser Welding are numerous and significant in various industries. Laser welding offers several advantages over traditional welding methods, making it a preferred choice for many applications. One of the key benefits is the precision it offers. The focused beam of the laser allows for precise control over the welding process, resulting in high-quality welds with minimal distortion. This accuracy is particularly beneficial in industries where precision is crucial, such as aerospace and automotive.

Another advantage of industrial laser welding is its speed. The concentrated heat of the laser beam allows for rapid welding, reducing production time and increasing efficiency. This is especially advantageous in industries where large volumes of welds need to be completed quickly, such as in the manufacturing of consumer electronics or medical devices.

Furthermore, laser welding provides a cleaner and more aesthetically pleasing weld compared to traditional welding methods. The laser beam produces a narrow and well-defined weld, minimizing the need for additional post-welding processes like grinding or polishing. This not only saves time but also improves the overall appearance of the finished product.

In addition, industrial laser welding offers enhanced flexibility. The laser beam can be easily manipulated and controlled, allowing for welding in tight spaces or intricate designs. This versatility makes laser welding suitable for a wide range of applications, from small delicate components to large structural welds.

Challenges Faced by Freelance Workers in Laser Welding

Freelance workers in laser welding often encounter a range of challenges that require technical expertise and adaptability to overcome. These challenges include:

- Limited access to equipment: Freelance workers may not have the same access to high-quality laser welding equipment as full-time employees. This can make it difficult to achieve the same level of precision and efficiency in their work.

- Lack of support and guidance: Without the structure and resources provided by a company, freelance workers may struggle to find the support and guidance they need to improve their laser welding skills. They may have to rely on their own research and experimentation to overcome technical challenges.

- Inconsistent work opportunities: Freelance workers in laser welding may face periods of inconsistent work and income. This can make it challenging to maintain a stable career and develop expertise in the field.

Despite these challenges, freelance workers in laser welding have the opportunity to develop a unique set of skills and adaptability. By staying up-to-date with the latest advancements in laser welding technology and seeking out professional development opportunities, freelance workers can overcome these challenges and thrive in their careers.

Key Insights for Improving Laser Welding Efficiency

After addressing the challenges faced by freelance workers in laser welding, it is crucial to explore key insights that can significantly improve laser welding efficiency. Efficiency is a key factor in the success of any laser welding operation, as it directly impacts productivity, cost-effectiveness, and overall quality. By implementing these insights, freelance workers can enhance their skills and contribute to the success of laser welding companies.

One key insight for improving laser welding efficiency is to optimize the welding parameters. This involves adjusting factors such as laser power, welding speed, focus position, and beam diameter to achieve the desired weld quality in the most efficient manner. By fine-tuning these parameters, freelancers can minimize the time and energy required for each weld, leading to increased efficiency.

Another important insight is to leverage automation and robotic systems. Automation can significantly improve laser welding efficiency by reducing human error and increasing the speed and precision of the welding process. Robotic systems can be programmed to perform repetitive welding tasks with great accuracy, freeing up freelance workers to focus on more complex or specialized welding operations.

Furthermore, proper maintenance and regular calibration of laser welding equipment are essential for maximizing efficiency. Regular maintenance ensures that the equipment is functioning optimally, minimizing downtime and the need for costly repairs. Calibrating the equipment regularly ensures accurate and consistent results, reducing the need for rework and increasing overall efficiency.

Leveraging Technology for Enhanced Laser Welding Performance

To achieve enhanced laser welding performance, leveraging advanced technology is crucial. By utilizing cutting-edge tools and equipment, welders can optimize their processes and produce high-quality welds efficiently.

Here are three ways that technology can be leveraged to improve laser welding performance:

- Automation: Integrating automated systems into the laser welding process can greatly enhance efficiency and precision. Automated systems can handle repetitive tasks, such as part positioning and beam alignment, with a high level of accuracy, reducing the risk of human error and increasing productivity.

- Real-time monitoring and control: Advanced monitoring and control systems allow welders to closely monitor the welding process in real-time. These systems provide data on parameters such as temperature, power, and speed, enabling welders to make immediate adjustments if needed. This real-time feedback helps ensure consistent weld quality and allows for prompt troubleshooting if any issues arise.

- Simulation and modeling: Technology allows for the simulation and modeling of welding processes before they are executed. This allows welders to optimize their welding parameters, predict potential defects, and identify the most efficient welding strategies. By simulating the process beforehand, welders can save time, reduce material waste, and achieve better overall welding performance.

Best Practices for Freelance Workers in the Laser Welding Industry

In order for freelance workers in the laser welding industry to optimize their performance, it is essential to adhere to best practices that ensure efficient and high-quality results. Laser welding is a complex process that requires precision and expertise. Freelancers must familiarize themselves with the latest technologies and techniques to stay competitive in the industry.

One of the best practices for freelance workers in the laser welding industry is to continuously update their knowledge and skills. This can be achieved by attending workshops, seminars, and training programs offered by industry experts. By staying up-to-date with the latest advancements in laser welding technology, freelancers can improve their efficiency and produce better results.

Another best practice is to maintain a clean and organized workspace. Laser welding requires a controlled environment to ensure accurate and consistent welds. Freelancers should keep their work area free from debris, dust, and other contaminants that can negatively impact the quality of the welds. Additionally, they should properly maintain their equipment and regularly calibrate it to ensure optimal performance.

Furthermore, communication and collaboration are crucial for freelance workers in the laser welding industry. They should establish strong relationships with suppliers, clients, and other professionals in the field. By fostering these connections, freelancers can gain access to valuable resources, support, and potential job opportunities.

Building Successful Partnerships in the Laser Welding Business

What strategies can freelance workers in the laser welding industry employ to build successful partnerships in the business? Here are three key approaches:

- Establishing a strong network: Freelancers can actively engage in networking events, industry conferences, and online communities to connect with potential partners. By building relationships with other professionals in the laser welding business, freelancers can increase their chances of finding mutually beneficial partnerships.

- Demonstrating expertise and reliability: In the laser welding industry, clients value expertise and reliability. Freelancers can establish themselves as trusted partners by showcasing their skills, knowledge, and experience. This can be done through a strong portfolio, testimonials from satisfied clients, and consistent delivery of high-quality work.

- Collaborative problem-solving: Successful partnerships thrive on effective communication and collaboration. Freelancers can actively engage with their partners, seeking their input and involving them in the decision-making process. By working together to solve problems and address challenges, freelancers can foster strong and long-lasting partnerships.

Building successful partnerships in the laser welding business requires a combination of networking, expertise, and collaboration. By employing these strategies, freelance workers can enhance their professional reputation, expand their network, and secure valuable partnerships in the industry.

Frequently Asked Questions

What Are Some Common Misconceptions About Industrial Laser Welding?

Common misconceptions about industrial laser welding include the belief that it is a complex and expensive process, that it is only suitable for certain materials, and that it is not as strong as traditional welding methods. However, with advancements in technology, laser welding has become more accessible, versatile, and reliable.

How Can Freelance Workers Overcome the Challenges of Working in the Laser Welding Industry?

Freelance workers in the laser welding industry can overcome challenges by acquiring specialized skills, staying updated on industry trends, and building a strong network. Adapting to changing technologies and maintaining a high level of professionalism are also crucial for success.

What Are Some Innovative Technologies That Can Be Used to Improve Laser Welding Performance?

Innovative technologies such as robotic-assisted laser welding systems and advanced monitoring systems can greatly enhance laser welding performance. These technologies offer increased precision, efficiency, and quality control, leading to improved overall productivity for laser welding companies.

What Are Some Tips for Freelance Workers to Enhance Their Efficiency in Laser Welding?

To enhance efficiency in laser welding, freelance workers should prioritize continuous training and education to stay updated on the latest techniques and technologies. Additionally, maintaining proper equipment maintenance and adhering to safety protocols are crucial for optimal performance.

How Can Freelance Workers in the Laser Welding Industry Establish Successful Partnerships With Other Businesses?

Freelance workers in the laser welding industry can establish successful partnerships with other businesses by networking, showcasing their expertise, and delivering high-quality work. Building a reputation for reliability and professionalism is crucial for fostering collaborations and expanding opportunities.

Conclusion

In conclusion, freelance workers in the laser welding industry have the potential to greatly enhance the operations of a laser welding company by implementing various strategies, techniques, and best practices. By optimizing laser parameters, ensuring proper equipment maintenance, and leveraging technology, these workers can improve efficiency and contribute to the growth and success of the industry. Effective communication and collaboration are also key in building strong professional relationships. With the right knowledge and tools, freelance workers can drive innovation and progress in the field of industrial laser welding.

You May Also Like: